catégories

Cosmetic Airless Pump Bottle & Jar Suppliers

-

15 ml 30 mL 50 ml 100 ml

Les Pots de Crème Cosmétique Sans Air Rechargeables Ronds dans 15 ml, 30 ml, 50 ml ET 100 ml de cLes Pots de Crème Cosmétique Sans Air Rechargeables Ronds dans 15 ml, 30 ml, 50 ml ET 100 ml de capacité le Summum de la Créativité de l'emballage dans L'industrie Cosmétique. Fabrique en P...

15 ml 30 mL 50 ml 100 ml

Les Pots de Crème Cosmétique Sans Air Rechargeables Ronds dans 15 ml, 30 ml, 50 ml ET 100 ml de cLes Pots de Crème Cosmétique Sans Air Rechargeables Ronds dans 15 ml, 30 ml, 50 ml ET 100 ml de capacité le Summum de la Créativité de l'emballage dans L'industrie Cosmétique. Fabrique en P... -

15 ml 30 ml 50 ml 100 ml de pot à pompe à l'air rechargeable à rond

L'Emballage de Pot à crème cosmétique sans air rechargeable Rond dans des capacités de 1L'Emballage de Pot à crème cosmétique sans air rechargeable Rond dans des capacités de 15 ml, 30 ml, 50 ml et 100 ml, ILS incarnent la conception de pointe dans l'industrie des cosmétique...

15 ml 30 ml 50 ml 100 ml de pot à pompe à l'air rechargeable à rond

L'Emballage de Pot à crème cosmétique sans air rechargeable Rond dans des capacités de 1L'Emballage de Pot à crème cosmétique sans air rechargeable Rond dans des capacités de 15 ml, 30 ml, 50 ml et 100 ml, ILS incarnent la conception de pointe dans l'industrie des cosmétique... -

30 ml 50 ml 100 ml 120 ml 150 ml 200 ml

30 ml 50 ml 100 ml 120 ml 150 ml 200 ml Les Bouteilles de Pompe pp vides pp offrent une solution de30 ml 50 ml 100 ml 120 ml 150 ml 200 ml Les Bouteilles de Pompe pp vides pp offrent une solution de solution polyvalente et pratique coullar une un grand gamme de produisés de soins de beauté. Ces Bo...

30 ml 50 ml 100 ml 120 ml 150 ml 200 ml

30 ml 50 ml 100 ml 120 ml 150 ml 200 ml Les Bouteilles de Pompe pp vides pp offrent une solution de30 ml 50 ml 100 ml 120 ml 150 ml 200 ml Les Bouteilles de Pompe pp vides pp offrent une solution de solution polyvalente et pratique coullar une un grand gamme de produisés de soins de beauté. Ces Bo... -

15 ml 30 ml 50 ml 80 ml 100 ml en tant que Bouteille de Lotion de Divisiseur Sans Air Portable

Car la Bouteille de distribution Sans Air Portable est un Choix pour l'Emballage des CosmétCar la Bouteille de distribution Sans Air Portable est un Choix pour l'Emballage des Cosmétiques et des Produits de Soines Personnels. Les clients peuvent les utiliser comm. Un avantage est l&...

15 ml 30 ml 50 ml 80 ml 100 ml en tant que Bouteille de Lotion de Divisiseur Sans Air Portable

Car la Bouteille de distribution Sans Air Portable est un Choix pour l'Emballage des CosmétCar la Bouteille de distribution Sans Air Portable est un Choix pour l'Emballage des Cosmétiques et des Produits de Soines Personnels. Les clients peuvent les utiliser comm. Un avantage est l&... -

Comme Bouteille sans air rond

Comme les Bouteilles sans Air Rond Sans Sans Air Combinsi, le style et les Fonctionnalités, ce quiComme les Bouteilles sans Air Rond Sans Sans Air Combinsi, le style et les Fonctionnalités, ce qui en fait un Chaux pour emballer Les Cosmétiques et les produits de personnel de Soins. Les clients pe...

Comme Bouteille sans air rond

Comme les Bouteilles sans Air Rond Sans Sans Air Combinsi, le style et les Fonctionnalités, ce quiComme les Bouteilles sans Air Rond Sans Sans Air Combinsi, le style et les Fonctionnalités, ce qui en fait un Chaux pour emballer Les Cosmétiques et les produits de personnel de Soins. Les clients pe... -

15 ml 30 ml 50 ml 80 ml Fondère de Pulvérisation Sans Air transparent Avec Pompe à Pulvérisation Blanche

15 ml 30 ml 50 ml 80 ml Fondère de Pulvérisation Sans Air Transparent Avec des Pompes à Pulvé15 ml 30 ml 50 ml 80 ml Fondère de Pulvérisation Sans Air Transparent Avec des Pompes à Pulvérisation Blanche est Conçue Avec la Transparence, Ce quit permet aux utilisateurs d'observateur Fac...

15 ml 30 ml 50 ml 80 ml Fondère de Pulvérisation Sans Air transparent Avec Pompe à Pulvérisation Blanche

15 ml 30 ml 50 ml 80 ml Fondère de Pulvérisation Sans Air Transparent Avec des Pompes à Pulvé15 ml 30 ml 50 ml 80 ml Fondère de Pulvérisation Sans Air Transparent Avec des Pompes à Pulvérisation Blanche est Conçue Avec la Transparence, Ce quit permet aux utilisateurs d'observateur Fac... -

Pompe de Lotion Cosmetic Spray Mousse émulsion dispensateur plastique transparent comm.

Pompe de lotion Cosmetic Spray Mousse Dispensateur Plastique transparent comme bouteilles sans aiPompe de lotion Cosmetic Spray Mousse Dispensateur Plastique transparent comme bouteilles sans air sous vide avec As Caps en plastique transparent, ce qui permet aux utilisateurs d'observer fa...

Pompe de Lotion Cosmetic Spray Mousse émulsion dispensateur plastique transparent comm.

Pompe de lotion Cosmetic Spray Mousse Dispensateur Plastique transparent comme bouteilles sans aiPompe de lotion Cosmetic Spray Mousse Dispensateur Plastique transparent comme bouteilles sans air sous vide avec As Caps en plastique transparent, ce qui permet aux utilisateurs d'observer fa... -

30 ml 50 ml 100 ml 150 ml de Bouteilles de Pompe sans air

Conçus couler le répondre à un gamme de besoins de distribution liquide, ces boules de pompe sanConçus couler le répondre à un gamme de besoins de distribution liquide, ces boules de pompe sans air offrent une solution sophistique et efficace qui va va au-delà de l'emballage conventionnel....

30 ml 50 ml 100 ml 150 ml de Bouteilles de Pompe sans air

Conçus couler le répondre à un gamme de besoins de distribution liquide, ces boules de pompe sanConçus couler le répondre à un gamme de besoins de distribution liquide, ces boules de pompe sans air offrent une solution sophistique et efficace qui va va au-delà de l'emballage conventionnel.... -

30 ml 50 ml pp Round Airless Click Cosmetic Cream Jar Callage

L'Emballage de Bocal à crème cosmétique de 30 ml et 50 ml de 30 ml de crème cosmétiqueL'Emballage de Bocal à crème cosmétique de 30 ml et 50 ml de 30 ml de crème cosmétique Sans Air est un exemple de la combinaison de la forme et de laonction dans le domaine des leins de la pEa...

30 ml 50 ml pp Round Airless Click Cosmetic Cream Jar Callage

L'Emballage de Bocal à crème cosmétique de 30 ml et 50 ml de 30 ml de crème cosmétiqueL'Emballage de Bocal à crème cosmétique de 30 ml et 50 ml de 30 ml de crème cosmétique Sans Air est un exemple de la combinaison de la forme et de laonction dans le domaine des leins de la pEa... -

30 ml 50 ml pp Jar de presse cosmétique sans air couler la pain deins de la pEau emballage

Les pots de presse cosmétiques sans air de 30 ml et 50 ml pp offrent une solution sophistique pourLes pots de presse cosmétiques sans air de 30 ml et 50 ml pp offrent une solution sophistique pour l'emballage des crème desines de la peau, incarnant un mélange de fonctionnalités et d'est...

30 ml 50 ml pp Jar de presse cosmétique sans air couler la pain deins de la pEau emballage

Les pots de presse cosmétiques sans air de 30 ml et 50 ml pp offrent une solution sophistique pourLes pots de presse cosmétiques sans air de 30 ml et 50 ml pp offrent une solution sophistique pour l'emballage des crème desines de la peau, incarnant un mélange de fonctionnalités et d'est...

À propos du Yiziman

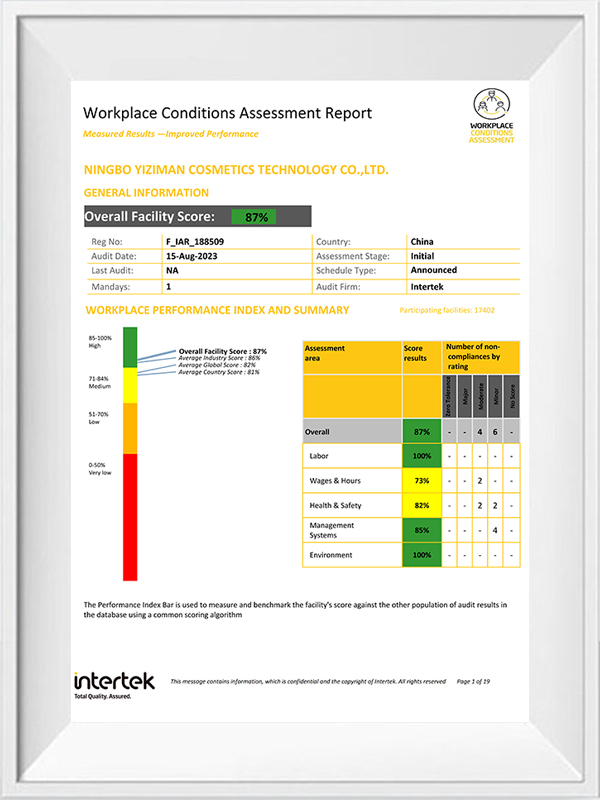

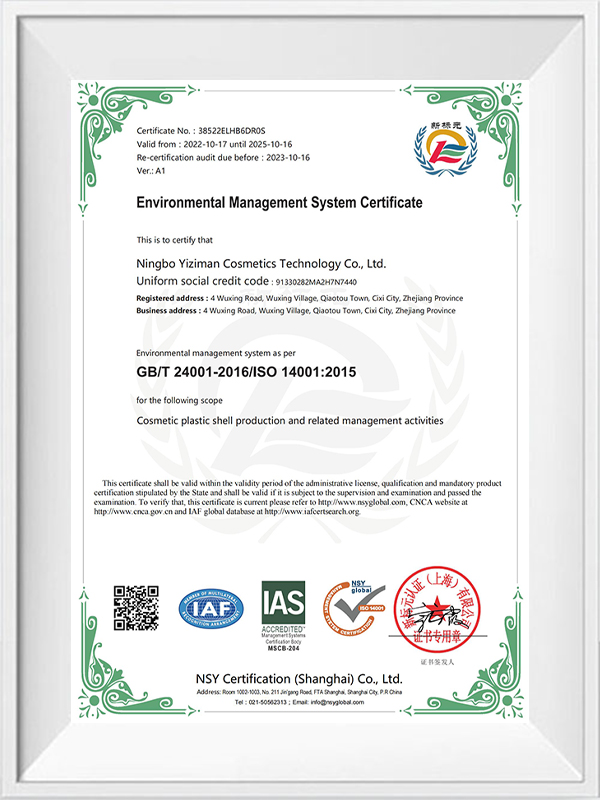

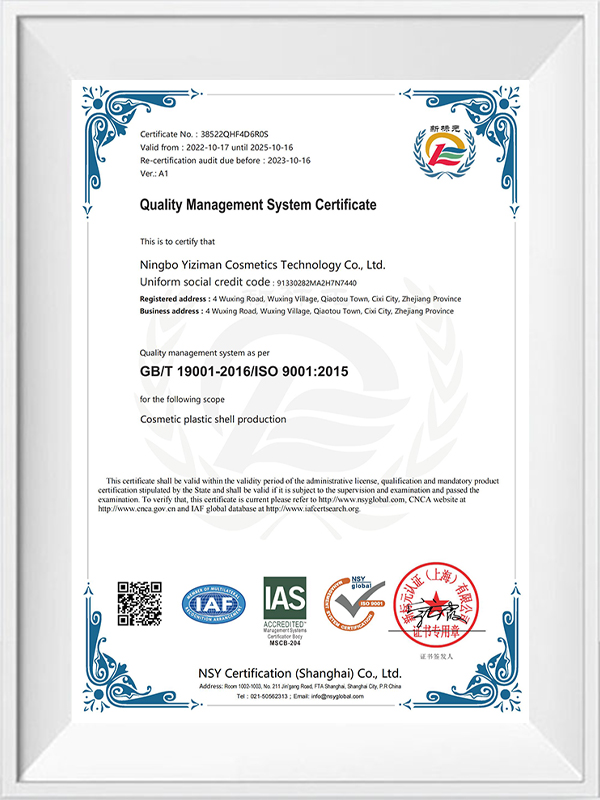

Ningbo Yiziman Cosmetics Technology Co., Ltd., créé en 2018 (anciennement connu sous le nom de Cixi Longyin Plastic Products Co., Ltd.), est un Cosmetic Airless Pump Bottle supplier et Cosmetic Airless Pump Jar company En Chine, que vous ayez besoin de matériel d'emballage standardisé ou de solutions personnalisées, nous avons l'expérience et la flexibilité pour garantir que vos produits se démarquent. Ningbo Yiziman détient la certification ISO 40001 et l'inspection de l'usine WCA, démontrant notre engagement envers la responsabilité environnementale et l'assurance qualité, ce qui donne à nos clients la confiance. Nous accordons une attention méticuleuse aux détails et offrons une gamme de techniques de finition de surface, telles que l'impression UV, l'impression de transfert de chaleur, l'estampage à chaud, la pulvérisation et l'électroples, pour garantir que nos produits répondent aux normes. Nos capacités de production robustes peuvent fabriquer plus de 3 millions d'unités d'emballage cosmétiques par mois. Professionnel wholesale Cosmetic Airless Pump bottle & Jar, Que vous ayez besoin de production en vrac ou que vous ayez des besoins de personnalisation spécifiques, nous pouvons rapidement répondre à vos besoins, garantir des produits de haute qualité et stables.

-

Services de personnalisation

Services de personnalisation

Développement et production personnalisés de produits selon des dessins ou des échantillons fournis par les clients

-

Rentabilité

Rentabilité

Vendre des produits directement et fournir des solutions à un bon prix

-

Qualité supérieure

Qualité supérieure

Équipé d'un équipement de test pour assurer la qualité du produit

-

Diversité

Diversité

Peu importe ce dont vous avez besoin, nous pouvons fournir une gamme complète de solutions.

-

Capacité de production élevée

Capacité de production élevée

Capacité de production forte, capable de répondre aux besoins des clients avec un volume d'achat différent

-

Marché international

Marché international

Notre qualité et notre service sont reconnus sur le marché international

Contactez-nous pour plus de détails

N'hésitez pas à contacter lorsque vous avez besoin de nous!

Dernières nouvelles et événements

Nous sommes un partenaire fiable qui façonne notre expertise dans le succès de votre projet.

Extension des connaissances de l'industrie

Nous sommes un partenaire fiable qui façonne notre expertise dans le succès de votre projet.